High temperature/humidity test chamber

High temperature and humidity test chamber is ideal to high and low temperature, high/low temperature cycle test of products (whole machine), parts and materials, as well as constant or alternating humidity and heat test. The test chamber can be used for heat and non-heat dissipation to test samples. For the heat dissipation test sample, its heat dissipation power cannot exceed the refrigeration capacity of the test chamber, because the refrigeration capacity is dynamic, it varies with the change of temperature point. At the same time, the higher humidity will be affected by condensation when the heat of the heat dissipation product needs to be cooled and balanced.

Specification

◆The same volume is subject to a large storage area and load heat;

◆Japanese new ELV refrigerant control technology is ideal to realize low temperature and energy-saving operation.

◆Prevent test items from dew condensation control conditions;

◆Communication configuration RS232 interface and USB storage/download function;

◆Multiple alarm monitoring of the machine and wireless remote alarm function;

◆Safe waterway system and recycling water circulation system

◆The maximum humidity effect can reach 5 C/5% RH, and makes the dehumidification speed fast.

◆Strong ability to prevent static electricity and reduce consumption, and achieves the best performance in the same industry.

Technological Innovation:

New PWM cold control technology enables low temperature energy saving operation. In the low temperature working state, the heater does not participate in the work. The PWM technology will control the refrigerant flow and flow direction of the refrigeration unit, and the three-way flow regulation of the refrigeration pipeline, the cold bypass pipeline, and the hot bypass pipeline is to realize the temperature of the working chamber automatically constant. This method can reduce energy consumption by 40% under low temperature conditions.

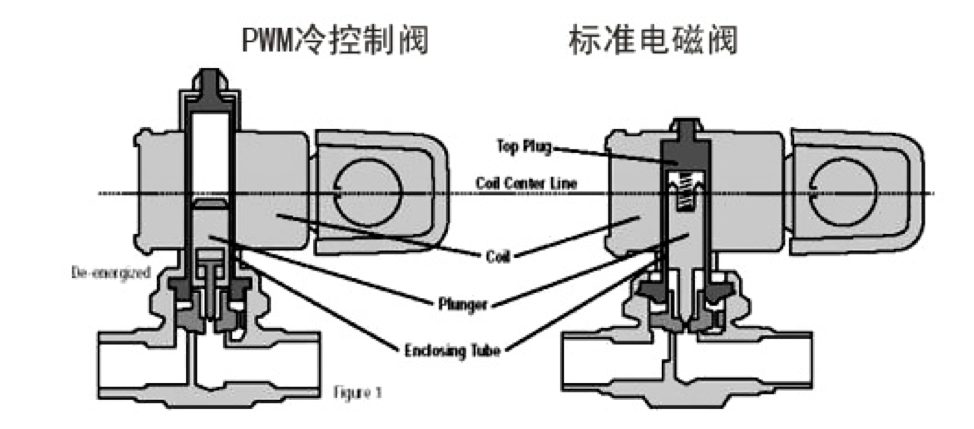

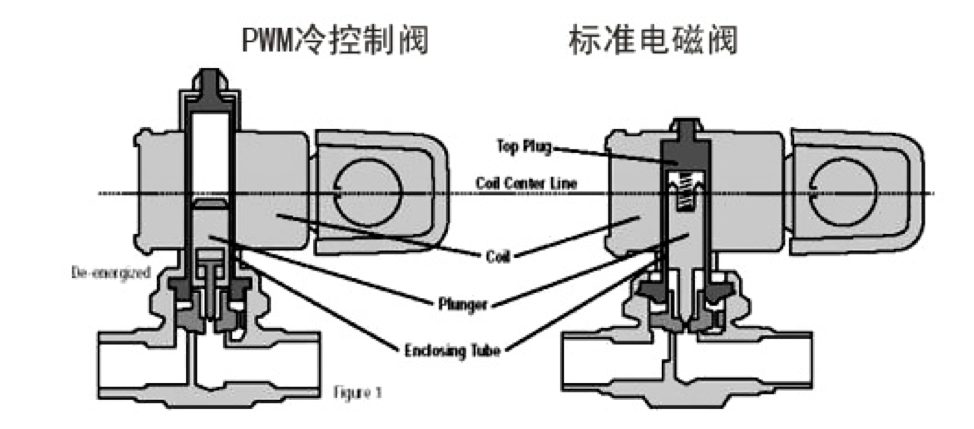

The technology is based on Sporlan's customized PWM control valve:

This technology regulates the flow of pipelines through frequent action of solenoid valves. Standard solenoid valves cannot adapt to the situation and metal fatigue damage will occur in a very short time. At present, only XM series products produced by Sporlan Company in the United States (this product cannot be imported from normal channels) can support this technology. The following figure shows the difference between solenoid valves.

Standard:

GB10589-89 Technical conditions of low temperature test chamber; GB10592-89 Technical conditions of high and low temperature test chamber;

GB11158Technical conditions of high temperature test chamber; GB/T10586-89 Technical conditions of humidity and heat test chamber;

GB/T2423.1-2008 Test method of low temperature test chamber; GB/T2423.2-2008 Test method of high temperature test chamber; GB/T2423.3-2006 Test method of damp/heat Test chamber;

GB/T2423.4-2008 Test method of damp/heat alternating; GB/T2423.22-2002 Test method of temperature changing; IEC60068-2-1.1990 Test method of low temperature test chamber;

IEC60068-2-2.1974 Test method of high temperature test chamber; GJB150.3 High temperature test; GJB150.4 Low temperature test; GJB150.9 Damp/heat test;

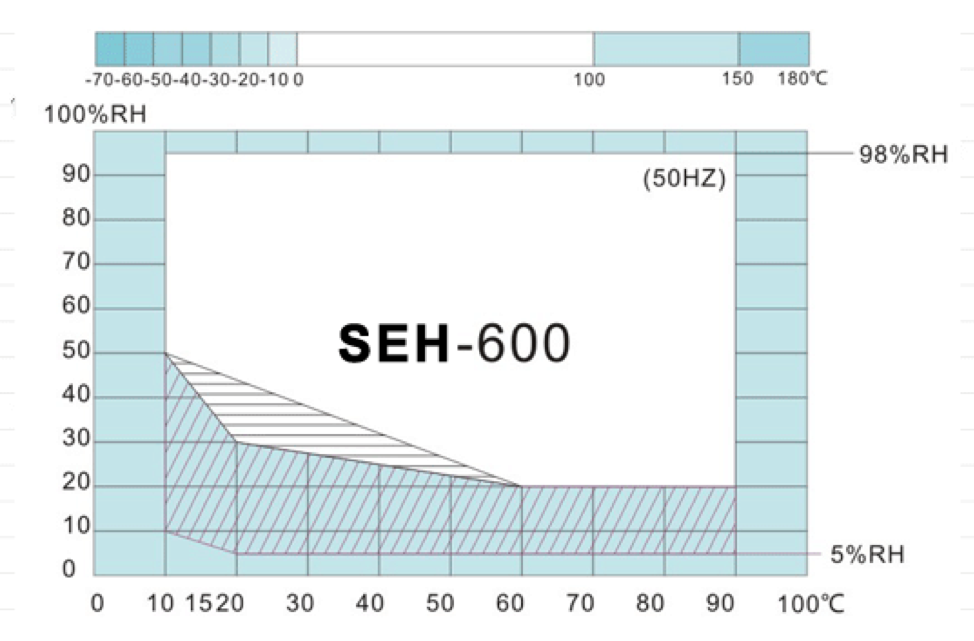

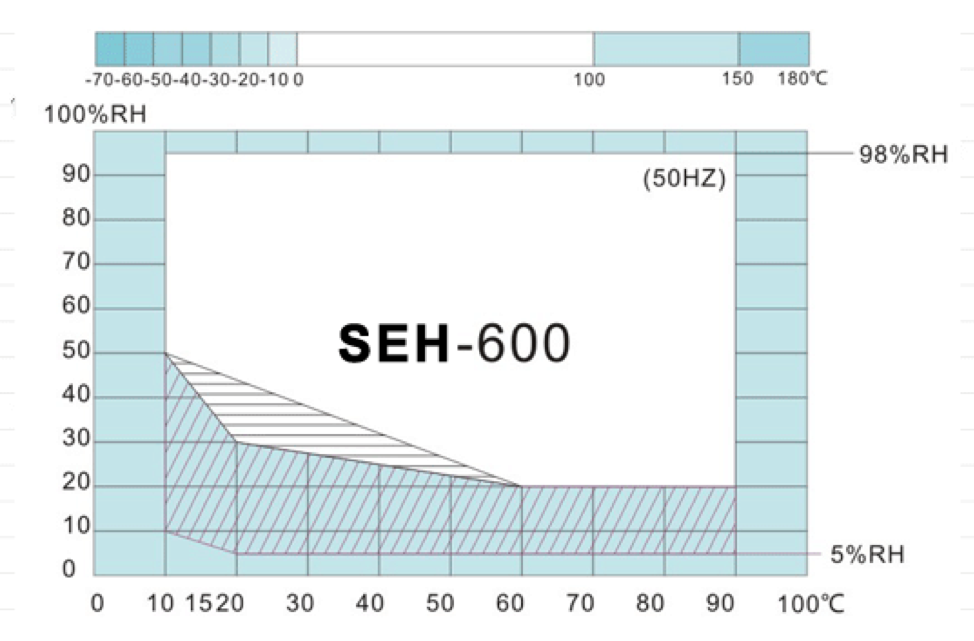

Temperature and humidity specification:

■ The oblique part is the curve of adding chemical dehumidification system;

■ The horizontal part is 60Hz and the rest is 50Hz curve.

■ 50Hz controllable capability range

■ Capability range of 60 Hz over 50 Hz

■ Capability range of installing dehumidifier

Specifications:

|

Model

|

GRO165

|

GRO408

|

GRO800

|

GRO1000

|

|

Interior Size (cm) W*D*H

|

50×50×660

|

60×80×100

|

100×80×100

|

100×100×100

|

|

External Size (cm) W*D*H

|

110×120×190

|

120×150×220

|

160×150×220

|

160×180×220

|

|

Parameter

|

Temperature Range

|

0℃/-20℃/-40℃/-70℃~+100℃/+150℃

|

|

Temperature Uniformity

|

≤2℃

|

|

Temperature Deviation

|

±2℃

|

|

Temperature Fluctuation

|

≤1℃(≤±0.5℃, according to GB/T5170-1996)

|

|

Heating Time

|

+20℃~+150℃/ 45min (No Load)

|

|

Cooling Time

|

+20℃~-20℃/30min/ +20℃~-40℃/50min/ +20℃~-70℃/60min/(No Load)

|

|

Humidity Range

|

(10) 20~98%RH

|

|

Humidity Deviation

|

±3%(>75%RH), ±5%(≤75%R)

|

|

Temperature Controller

|

Chinese color touch screen + PLC controller (Self-development of control software)

|

|

Adaptability of Cryogenic System

|

Unique design meets automatic operation of compressor in full temperature range

|

|

Equipment Operation Mode

|

Fixed Value Running and Program Running

|

|

Cooling System

|

Refrigeration Compressor

|

Imported fully enclosed compressor

|

|

Cooling Method

|

Air (Water for option)

|

|

Humidifying water

|

Distilled or deionized water

|

|

Protection

|

Leakage, Short Circuit, Overtemperature, Water Shortage, Motor Overheating, Compressor Overpressure, Overload, Overcurrent

|

|

Standard Devices

|

Test Shelf (2 sets), Viewing Window, Lamp, Cable Hole, Caster

|

|

Power Supply

|

AC380V 50Hz Three-phase Four-wire + Grounding Wire

|

|

Material

|

Case Materia

|

Electrostatic Spraying of Cold Rolled Steel Plate

|

|

Inner wall material

|

SUS304 Stainless steel plate

|

|

Thermal insulation material

|

Rigid polyurethane foam

|